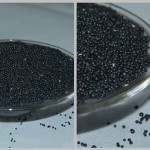

Chromite Sand Refractory chromite in granular form (chromite sand) is widely used in the foundry industry for both ferrous and non-ferrous castings, particularly in the automotive, shipbuilding and heavy-engineering sectors. The merits of chromite foundry sands include high refractoriness, good chemical stability, low thermal expansion – which means the mould retains a stable size – and high density and thermal conductivity (which promote rapid solidification of the casting). Chromite sand main characteristics: Melting Temperature is 2150 ̊C High Thermal Conductivity High Heat and Thermal shock Resistance Slag Resistant Stable Shape due to the Heat Analysis Result % AFS 51.59… Read more…

Ceramic Sand Ceramic Sand has lower cost and better performance than Chromites sand and Zircon sand, it will provide the effective ways to improve the quality of the foundry part, reduce cost and friendly to the environment. The chemical and physical characteristics are Ceramic Sand Properties Main Chemical Element Al2O3: 75 % Min Fe2O3: 5 % Max TiO: 5 % Max SiO2: 5~20 % KO: 1.5 % MgO: 0.5 % Ca: 0.55 % Shape Ball Shape Bulk Density (g/cm3) 1.95~2.05 Refractoriness ( ̊C min) 1790 Thermal Expansion 0.13 % pH 7.5 Ceramic Sand has advantages as… Read more…